(888) 782-8338

ErgoMatters℠ is moving to SafeAtWorkCA.com, State Fund’s safety resource center. Click the link below to find all of our ErgoMatters content. ErgoMatters on SafeAtWorkCA.com |

Employees’ arms, shoulders, and backs are exposed to fatigue and potential injury when constantly working with manual and power hand tools. The weight of the tool applies force to the shoulders and back every time the employee handles, positions, and activates the tool(s). While the weight of the tool may be relatively light (.5 to 10 pounds), over time, the static postures combined with the weight and force of the tool, add up, ultimately leave the employees feeling fatigued and leading to a greater likelihood of an injury occurring.

Force refers to the amount of physical effort that is required to accomplish a task or motion. Tasks or motions that require application of higher force place higher mechanical loads on muscles, tendons, ligaments, and joints, in this case, the neck, shoulders and wrists. Tasks involving high forces may cause muscles to fatigue more quickly. High forces also may lead to irritation, inflammation, strains, and tears of muscles, tendon, and other tissues.

The force required to complete a movement increases when other risk factors are also involved. For example, more physical effort may be needed to perform tasks when the speed or acceleration of motions increases, when vibration is present, or when the task also requires awkward postures.

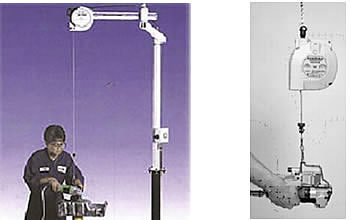

For belt sanders, screwdrivers, nail guns, and for any other tools that have to be used frequently throughout a shift, consider introducing a counter-weight system, also called "balancers" to take up the weight of the tool.

Tool balancers not only support the tool but also reduce torque reaction transmitted to the operator. The risk of fatigue and injury is reduced because only a light, downward force is required to place the tool in proper operating position. Balancers can accommodate tools weighing up to 187 pounds. Look for balancers that move with the tool usage and the employee—meaning that it travels easily into position, not forcing the employee to pull against the support or power source. A good balancer presents the tool over the work with easy access and minimal travel.

Revised: 04/2017